Stretchability and Deformation Behavior of Polybutylene Adipate-co-terephthalate Blend Films

DOI:

https://doi.org/10.53848/ssstj.v9i2.230Keywords:

Elasticity, Polybutylene adipate-co-terephthalate, Biodegradable plastics, StretchabilityAbstract

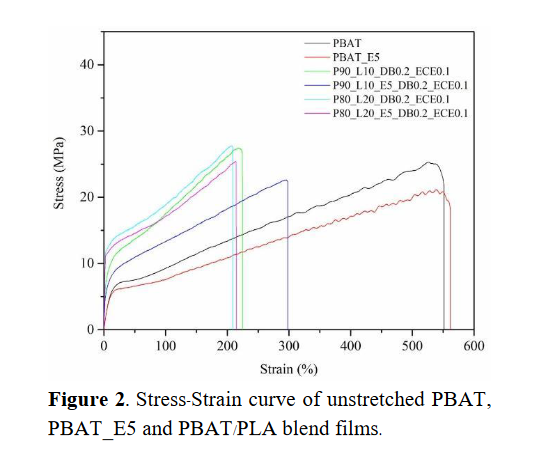

The single use packaging is widely used in various products; ranging from food to non-food contact, from commodity to specialty purposes. Most of these materials are derived from non-renewable fossil resources. In a sustainable manner, it needs to be recyclable or compostable. Good mechanical properties together with biodegradability can make the product more recyclable. In this study, the elasticity for films consisting of polybutylene adipate-co-terephthalate (PBAT) blended with polylactic acid (PLA) (10, and 20 %wt), additive and reactive agents were evaluated. The blends were prepared via a twin-screw extruder. The film specimens were prepared by cast film extrusion. The films were then stretched with different ratios (1.5, 2 and 2.5 times) by the uniaxial machine. The mechanical properties, elasticities and surface morphology of uniaxially stretched PBAT and PBAT blend films were characterized by tensile testing and scanning electron microscope (SEM), respectively. The tensile strength of stretched films tended to improve while the elongation at break reduced at higher stretching ratios. The surface morphology of stretched films revealed that the degree of orientation was increased after higher stretching ratios. The ability to recover in the plastic deformation region of stretched films was increased at the higher stretching ratios.

References

BASF. (2013). Product Information ecoflex® F blend C 1200. Retrieved from https://www.google.com/url?sa=t&rct=j&q=&esrc=s&source=web&cd=&ved=2ahUKEwikruTnidT3AhVE7XMBHXr4CTEQFnoECAgQAQ&url=https%3A%2F%2Fdocuments.basf.com%2Fc32f5c099d8e29ac42869b975517bdbdda6e62f4&usg=AOvVaw19kOzNTgIMyvLSuz_njoU7

Chen, Y., Han, L., Zhang, H., & Dong, L. (2021). Improvement of the strength and toughness

of biodegradable polylactide/silica nanocomposites by uniaxial pre-stretching. International Journal of Biological Macromolecules, 190, 198-205. doi:10.1016/j.ijbiomac.2021.08.218

Deng, Y., Yu, C., Wongwiwattana, P., & Thomas, N. L. (2018). Optimising ductility of poly (lacticacid) /poly(butylene adipate-coterephthalate) blends through co-continuous phase morphology. Journal of Polymers and the Environment, 26, 3802-3816. doi:10.1007/s10924-018-1256-x

European Bioplastics. (2020). Bioplastics market data. Retrieved from https://www. europeanbioplastics.org/market/

Hongdilokkul, P., Keeratipinit, K., Chawthai, S., Hararak, B., Seadan, M., & Suttiruengwong, S. (2015). A study on properties of PLA/PBAT from blown film process. IOP Conference Series: Materials Science and Engineering, 87, 012112. doi:10.1088/1757-899x/87/1/012112

Li, X., Yan, X., Yang, J., Pan, H., Gao, G., Zhang, H., & Dong, L. (2017). Improvement of compatibility and mechanical properties of the poly (lactic acid)/poly (butylene adipateco-terephthalate) blends and films by reactive extrusion with chain extender. Polymer Engineering and Science, 58. doi:10.1002/pen.24795

Likittanaprasong, N., Seadan, M., & Suttiruengwong, S. (2015). Impact property enhancement of poly (lactic acid) with different flexible copolymers. IOP Conference Series: Materials Science and Engineering, 87, 012069. doi:10.1088/1757-899x/87/1/012069

Pietrosanto, A., Scarfato, P., Di Maio, L., & Incarnato, L. (2020). Development of ecosustainable PBAT-based blown films and performance analysis for food packaging applications. Materials, 13(23), 5395.

Pitivut, S., Suttiruengwong, S., & Seadan, M. (2015). Effect of reactive agent and transesterification catalyst on properties of PLA/PBAT blends. IOP Conference Series: Materials Science and Engineering, 87, 012090. doi:10.1088/1757-899x/87/1/012090

SeedScientific. (2021). 51+ Disturbing plastic waste statistics. Retrieved from https://seedscientific.com/plastic-wastestatistics/

Su, S., Duhme, M., & Kopitzky, R. (2020). Uncompatibilized PBAT/PLA blends: Manufacturability, miscibility and properties. Materials, 13(21), 4897. doi:10.3390/ma13214897