Sound Absorbing Panels from Poly(lactic acid) Non-woven Fabric and Natural Fibers

DOI:

https://doi.org/10.53848/ssstj.v9i2.237Keywords:

Sound absorbing panel, Poly(lactic acid), Nonwoven, Hemp fiberAbstract

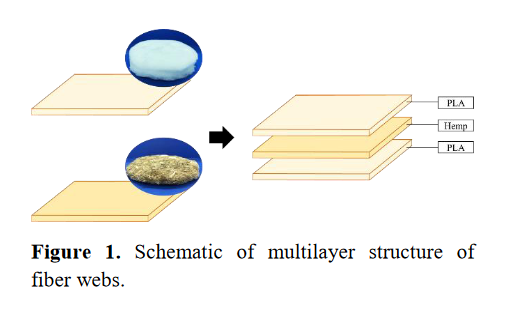

This research studied the utilization of biodegradable polymer for nonwoven fabric production and applied to fabricate a sound absorbing panel by corporate with natural fiber nonwoven fabric. PLA was used as a biodegradable polymer and hemp nonwoven was used as a natural fiber nonwoven fabric. PLA nonwoven fabric was prepared using a melt jet spinning process. The spinning process was carried out at 250 and 260°C with screw speed of 10 rpm and air blown pressure of 0.3 and 0.5 MPa. The die-to-collector of fabric production was studied at 30 and 60 cm to compare the nonwoven fabric product property. It was found that the process temperature, air pressure and die-to-collector distance have significant effects on the nonwoven fabric thickness, GSM, and fabric density. Air permeability decreased with high fabric thickness as well as fine fibers which supported the property of sound absorbing panels. Therefore, the suitable conditions for sound absorbing panel fabrication were processed at temperature of 260°C, air pressure 0.5 MPa and die-to-collector distance of 60 cm. Sound absorbing coefficient measurement revealed that GSM fabric thickness had an effect on increasing sound absorption. The effect of nonwoven sheet order and arrangement of PLA nonwoven and hemp nonwoven of 3 layers sandwich indicated that the layers order of PLA/PLA/Hemp had high sound absorbing coefficient that was comparable with PLA/PLA/PLA due to fiber size and arrangement.

References

Al-Shammari, B., Al-Fariss, T., Al-Sewailm, F., & Elleithy, R. (2011). The effect of polymer concentration and temperature on the rheological behavior of metallocene linear low density polyethylene (mLLDPE) solutions. Journal of King Saud University – Engineering Sciences, 23(1), 9-14. doi:10.1016/j.jksues.2010.07.001

Benkreira, H., Khan, A., & Horoshenkov, K. V. (2011). Sustainable acoustic and thermal insulation materials from elastomeric waste residues. Chemical Engineering Science, 66(18), 4157-4171. doi:10.1016/j.ces.2011.05.047

Broda, J., & Baczek, M. (2020). Acoustic properties of multi-layer wool nonwoven structures. Journal of Natural Fibers, 17(11), 1567-1581. doi:10.1080/15440478.2019.1584078

Chavan, A. T., & Manik, D. N. (2008). Optimum design of vibro-acoustic systems using SEA. International Journal of Acoustics and Vibrations, 13(2), 67-72.

Chen, T., & Huang, X. (2003). Modeling polymer air drawing in the melt blowing nonwoven process. Textile Research Journal, 73(7), 651-654. doi:10.1177/004051750307300715

Chen, T., Wang, X., & Huang, X. (2004). Modeling the air-jet flow field of a dual slot die in the melt blowing nonwoven process. Textile Research Journal, 74(11), 1018-1024 doi:10.1177/004051750407401114

Coates, M., & Kierzkowski, M. (2002). Acoustic textiles – Lighter, thinner and more absorbent. Technical Textile International, 11(7), 15-18.

Devi, R. P. (2014). A study on acoustic properties of polyester and hollow polyester non woven fabrics. International Journal of Advanced Technology in Engineering and Science, 2, 446-459.

Ellison, C. J., Phatak, A., Giles, D. W., Macosko, C. W., & Bates, F. S. (2007). Melt blown nanofibers: Fiber diameter distributions and onset of fiber breakup. Polymer, 48(11), 3306-3316. doi:10.1016/j.polymer.2007.04.005

Ganesan, P., & Karthik, T. (2016). Development of acoustic nonwoven materials from kapok and milkweed fibres. The Journal of The Textile Institute, 107(4), 477-482. doi:10.1080/00405000.2015.1045251

Korte, S., & Staiger, M. P. (2008). Effect of processing route on the composition and properties of hemp fibre. Fibers and Polymers, 9, 593-603. doi:10.1007/ s12221-008-0095-0

Kucuk, M., & Korkmaz, Y. (2012). The effect of physical parameters on sound absorption properties of natural fiber mixed nonwoven composites. Textile Research Journal, 82(20), 2043-2053. doi:10.1177/0040517 512441987

Lee, Y., & Wadsworth, L. C. (1990). Structure and filtration properties of melt blown polypropylene webs. Polymer Engineering and Science, 30(22), 1413-1419. doi:10.1002/pen.760302202

Mohammad, M., Nik Syukri, N. I. R., & Nuawi, M. Z. (2019). Sound properties investigation of date palm fiber. Journal of Physics: Conference Series, 1150(1). doi:10.1088/1742-6596/1150/1/012003

Oh, K. W., Kim, D. K., & Kim, S. H. (2009). Ultraporous flexible PET/Aerogel blanket for sound absorption and thermal insulation. Fibers and Polymers, 10(5), 731-737, doi:10.1007/s12221-010-0731-3

Prahsarn, C., Klinsukhon, W., Suwannamek, N., Wannid, P., & Padee, S. (2020). Sound absorption performance of needle-punched nonwovens and their composites with perforated rubber. SN Applied Sciences, 2(4). doi:10.1007/s42452-020-2401-4

PricewaterhouseCoopers. (2007). The automotive industry and climate change. Retrieved from http://www.pwc.com/th/en/automotive/assets/co2

Putra, A., Khair, F. A., & Nor, M. J. M. (2015). Utilizing hollow-structured bamboo as natural sound absorber. Archives of Acoustics, 40(4), 601-608. doi:10.1515/aoa-2015-0060

Qui, H., & Enhui, Y. (2018). Effect of thickness, density and cavity depth on the sound absorption properties of wool boards. Autex Research Journal, 18(2), 203-208. doi:10.1515/aut-2017-0020

Ren, M., & Jacobsen, F. (1993). A method of measuring the dynamic flow resistance and reactance of porous materials. Applied Acoustics, 39(4), 265-276. doi:10.1016/0003-682X(93)90010-4

Sengupta, S. (2010). Sound reduction by needlepunched nonwoven fabrics. Indian Journal of Fibre and Textile Research, 35(3), 237-242.

Tascan, M., & Vaughn, E. A. (2008). Effects of total surface area and fabric density on the acoustical behavior of needlepunched nonwoven fabrics. Textile Research Journal, 78(4), 289-296. doi:10.1177/0040517507084283

Watanabe, K., Kim, B. S., & Kim, I. S. (2011). Development of polypropylene nanofiber production system. Polymer Reviews, 51(3), 288-308. doi:10.1080/15583724.2011.594195

Wertel, S. J. (2000). Experimental analysis of noise reduction properties of sound absorbing foam. (Master’s thesis). University of WisconsinStout, Menomonie.

Yang, T., Xiong, X., Mishra, R., Novák, J., Chaloupek, J., Sanetrnik, F., & Militký, J. (2016). Investigation on acoustic behavior and air permeability of struto nonwovens. Fibers and Polymers, 17(12), 2078-2084. doi:10.1007/s12221-016-6967-9

Yilmaz, N. D. (2009). Acoustic properties of biodegradable nonwovens (Doctoral dissertation). North Carolina State University, North Carolina.

Yilmaz, N. D., Banks-Lee, P., Powell, N. B., & Michielsen, S. (2011). Effects of porosity, fiber size, and layering sequence on sound absorption performance of needle-punched nonwovens. Journal of Applied Polymer Science, 121(5), 3056-3069. doi:10.1002/ app.33312

Zhu, W., Nandikolla, V., & George, B. (2015). Effect of bulk density on the acoustic performance of thermally bonded nonwovens. Journal of Engineered Fibers and Fabrics, 10(3), 39-45. doi:10.1177/155892501501000316