Calcium Lactate as Renewable Filler of Polypropylene: Thermal, Morphological and Mechanical Properties

Keywords:

Biocomposite, Renewable filler, Calcium lactate, Polypropylene, CrystallizationAbstract

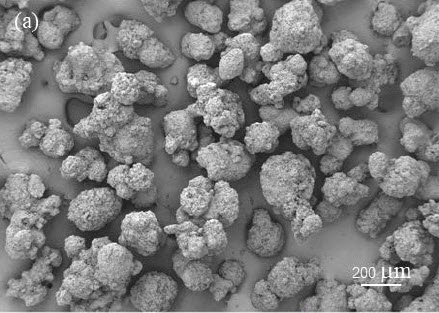

Polypropylene (PP) composites were prepared with calcium lactate (CL) at various loading levels (10-40 wt%) by melt mixing then injection molding. The resulting properties of composites were investigated by melt flow index, optical microscopy, differential scanning calorimetry, tensile, flexural and impact mechanical tests. The tensile/flexural moduli increased with increasing CL content, while the elongation at break decreased with increasing CL content. The highest tensile/flexural strengths and impact strength were found at 10 wt% CL content. The crystallization of PP initiated at higher temperature as a result of CL addition. The smaller spherulite size with the presence of CL provided the higher tie molecules, thus improving impact strength. The influence of the maleic anhydride grafted polypropylene (MAPP) as coupling agent on the properties of PP containing 10 wt% CL content was examined. The results revealed that the MAPP gave an insignificant improvement in the final properties of the composites.

References

Abdelwahab, M. A., Misra, M., & Mohanty, A. K. (2019). Injection molded biocomposites from polypropylene and lignin: Effect of compatibilizers on interfacial adhesion and performance. Industrial Crops and Products, 132, 497-510. doi:10.1016/j.indcrop.2019. 02.026

Altay, L., Atagur, M., Sever, K., Sen, I., Uysalman, T., Seki, Y., & Sarikanat, M. (2019). Synergistic effects of graphene nanoplatelets in thermally conductive synthetic graphite filled polypropylene composite. Polymer Composites, 40(1), 277-287. doi:10.1002/pc.24643

Bikiaris, D. N., Vassiliou, A., Pavlidou, E., & Karayannidis, G. P. (2005). Compatibilisation effect of PP-g-MA copolymer on iPP/SiO2 nanocomposites prepared by melt mixing. European Polymer Journal, 41, 1965-1978. doi:10.1016/j.eurpolymj.2005.03.008

Bledzki, A. K., Franciszczak, P., Osman, Z., & Elbadawi, M. (2015). Polypropylene biocomposites reinforced with softwood, abaca, jute, and kenaf fibers. Industrial Crops and Products, 70, 91-99. doi:10.1016/j.indcrop. 2015.03.013

Das, O., Bhattacharyya, D., Hui, D., & Lau, K.-T. (2016). Mechanical and flammability characterisations of biochar/polypropylene biocomposites. Composites Part B, 106, 120-128. doi:10.1016/j.compositesb.2016.09.020

Escócio, V. A., Pacheco, E. B. A. V., Silva, A. L. N., Cavalcante, A. P., & Visconte, L. L. Y. (2015). Rheological behavior of renewable polyethylene (HDPE) composites and spongegourd (Luffa cylindrica) residue. International Journal of Polymer Science, 2015. doi:10.1155/2015/714352

Essabir, H., Raji, M., Laaziz, S. A., Rodrique, D., Bouhfid, R., & Qaiss, A. E. K. (2018). Thermo-mechanical performances of polypropylene biocomposites based on untreated, treated and compatibilized spent coffee grounds. Composites Part B, 149, 1-11. doi:10.1016/j.

compositesb.2018.05.020

Garcia, M., van Vliet, G., Jain, S. , Schrauwen, B. A. G., Sarkissov, A., van Zyl, W. E., & Boukamp, B. A. (2005). Polypropylene/SiO2 nanocomposites with improved mechanical properties. Reviews on Advanced Materials Science, 6(2), 169-175.

Hwang, T. I., Kim, J. I., Joshi, M. K., & Park, C. H. (2019). Simultaneous regeneration of calcium lactate and cellulose into PCL nanofiber for biomedical application. Carbohydrate Polymers, 212, 21-29. doi:10.1016/j.carbpol. 2019.01.085

Liao, N., Joshi, M. K., Tiwari, A. P., Park, C. H., & Kim, C. S. (2016). Fabrication, characterization and biomedical application of two-nozzle electrospun polycaprolactone/zein-calcium lactate composite nonwoven mat. Journal of the Mechanical Behavior of Biomedical Materials, 60, 312-323. doi:10.1016/j.jmbbm.2016.02.006

Mir, S. S., Nafsin, N., Hasan, M., Hasan, N., & Hassan, A. (2013). Improvement of physico-mechanical properties of coir-polypropylene biocomposites by fiber chemical treatment. Materials and Design, 52, 251-257. doi:10.1016/j.matdes.2013.05.062

Mucha, M. & Krolikowski, Z. J. (2003). Application of DSC to study crystallization kinetics of polypropylene containing fillers. Journal of Thermal Analysis and Calorimetry , 74(2),549-557. doi.org/10.1023/B:JTAN.0000005193.66789.ea

Oliver-Ortega, H., Chamorro-Trenado, M. A., Soler, J., Mutjé, P., Vilaseca, F., & Espinach, F. X. (2018). Macro and micromechanical preliminary assessment of the tensile strength of particulate rapeseed sawdust reinforced polypropylene copolymer biocomposites for its use as building material. Construction and Building Materials, 168, 422-430. doi:10.1016/j.conbuildmat.2018.02.158

Padden, F. J., & Keith, H. D. (1959). Spherulitic crystallization in polypropylene. Journal of Applied Physics, 30, 1479. doi:10.1063/1. 1734985

Palza, H., Vera, J., Wilhelm, M., & Zapata, P. (2011). Spherulite growth rate in polypropylene/silica nanoparticle composites: Effect of particle morphology and compatibilizer. Macromolecular Materials and Engineering, 296(8), 744-751. doi:10.1002/mame.201000405

Pant, H. R., Risal, P., Park, C. H., Tijing, L. D., Jeong, Y. J., & Kim, C. S. (2013). Synthesis, characterization, and mineralization of polyamide-6/calcium lactate composite nanofibers for bone tissue engineering. Colloids and Surfaces B: Biointerfaces, 102, 152-157. doi:10.1016/j.colsurfb.2012.08.032

Poletto, M. (2018). Influence of coupling agents on rheological, thermal expansion and morphological properties of recycled polypropylene wood flour composites. Maderas: Ciencia y Tecnología, 20(4), 563- 570. doi:10.4067/S0718-221X2018005004401

Sedlarik, V., Galya, T., Emri, I., & Saha, P. (2009). Structure and conditioning effect on mechanical behavior of poly (vinyl alcohol)/calcium lactate biocomposites. Polymer Composites, 30(8), 1158-1165. doi:10.1002/pc.20672

Soleimani, M., Tabil, L., Panigrahi, S., & Opoku, A. (2008). The effect of fiber pretreatment and compatibilizer on mechanical and physical properties of flax fiber-polypropylene composites. Journal of Polymers and the Environment, 16, 74-82. doi:10.1007/s10924-008-0102-y

Xu, K., & Xu, P. (2014). Efficient calcium lactate production by fermentation coupled with crystallization-based in situ product removal. Bioresource Technology, 163, 33-39. doi:10.1016/j.biortech.2014.04.002

Xu, T., Yu, J., & Jin, Z. (2001). Effects of crystalline morphology on the impact behavior of polypropylene. Materials and Design, 22, 27-31. doi:10.1016/S0261-3069(00)00033-9