Impact of the Hybrid-Aluminum Additive on the Hydration Kinetics of Portland Cement in Fiber-Reinforced Cement Composites

DOI:

https://doi.org/10.53848/ssstj.v10i1.430Keywords:

Hydration, Cement, Additive, Circular economy, Recycling, WasteAbstract

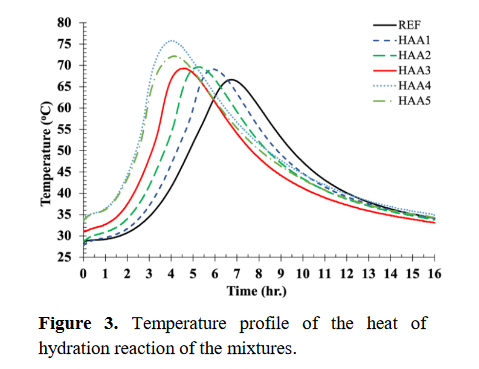

A hybrid-aluminum additive (HAA) synthesized from industrial wastes including aluminum dross and flue gas desulfurized (FGD) gypsum was used as an additive for fiber-reinforced cement composites (FRCC). The impact of this additive on hydration kinetics was observed by the temperature change over time for the various HAA mixtures with ordinary Portland cement (OPC), sand, cellulose fibers, polyvinyl alcohol (PVA) fibers, and water, based on the method described in ASTM C186-98. The results showed that the hydration kinetics of OPC in the FRCC was improved by using HAA. In addition, when the amount of HAA was at 3% of the OPC weight, the hydration reaction rate was improved by 41%. The HAA additive acted as an accelerating agent by shortening the setting time and enhancing the temperature of the hydration reaction. This suggests that the cement paste can set faster, reducing the cycle time in FRCC processing. Even though further addition of the HAA increased the reaction rate, the setting time of OPC was too short to form a green sheet for the actual production of FRCC on an industrial scale. In addition, the heat released during the test, representing by the temperature change of the sample, was too high which could have a negative impact on the finished FRCC products.

References

ASTM International. (1998). ASTM C186-98: Standard test method for heat of hydration of hydraulic cement. West Conshohocken, PA.

Askeland, D. R., Fulay, P. P., & Wright, W. J. (2010). The science and engineering of materials. Stamford, CT: Cengage Learning.

Azarhomayun, F., Haji, M., Kioumarsi, M., & Shekarchi, M. (2022). Effect of calcium stearate and aluminum powder on free and restrained drying shrinkage, crack characteristic and mechanical properties of concrete. Cement and Concrete Composites, 125, 104276.doi:10.1016/j.cemconcomp.2021.104276

Chakartnarodom, P., Kongkajun, N., Chuankrerkkul, N., Ineure, P., & Prakaypan, W. (2019). Reducing water absorption of fiber-cement composites for exterior applications by crystal modification method. Journal of Metals, Materials and Minerals, 29(4), 90-98.

Chakartnarodom, P., Prakaypan, W., Ineure, P., Chuankrerkkul, N., Laitila, E. A., & Kongkajun, N. (2020). Properties and performance of the basalt-fiber reinforced texture roof tiles. Case Studies in Construction Materials, 13. doi:10.1016/j.cscm.2020.e00444

Chakartnarodom, P., Prakaypan, W., Ineure, P., Kongkajun, N., & Chuankrerkkul, N. (2018). Feasibility study of using basalt fibers as the reinforcement phase in fiber-cement products. Key Engineering Materials, 766, 252-257.

Chakartnarodom, P., Wanpen, S., Prakaypan, W., Laitila, E. A., & Kongkajun, N. (2022). Development of high-performance fiber cement: A case study in the integration of circular economy in product design. Sustainability, 14(19). doi:10.3390/su141912263

Chen, C. Y., Shen, Z. Y., & Lee, M. T. (2021). On developing a hydrophobic rubberized cement paste. Materials, 14(13). doi:10.3390/ma14133687

Chen, C., & Sun, Z. (2018). Influence of aluminum sulfate on hydration and properties of cement pastes. Journal of Advanced Concrete Technology, 16(10), 522-530.doi:10.3151/jact.16.522

Khorami, M., & Ganjian, E. (2011). Comparing flexural behaviour of fibre–cement composites reinforced bagasse: Wheat and eucalyptus. Construction and Building Materials, 25(9), 3661-3667. doi:10.1016/j.conbuildmat.2011.03.052

Kongkajun, N., Laitila, E. A., Ineure, P., Prakaypan, W., Cherdhirunkorn, B., & Chakartnarodom, P. (2020). Soil-cement bricks produced from local clay brick waste and soft sludge from fiber cement production. Case Studies in Construction Materials, 13.

doi:10.1016/j.cscm.2020.e00448

Lagazzo, A., Vicini, S., Cattaneo, C., & Botter, R. (2016). Effect of fatty acid soap on microstructure of lime-cement mortar. Construction and Building Materials, 116, 384-390. doi:10.1016/j.conbuildmat.2016.04.122

Li, C., Zhou, A., Zeng, J., Liu, Z., & Zhang, Z. (2019). Influence of MFPSA on mechanical and hydrophobic behaviour of fiber cement products. Construction and Building Materials, 223, 1016-1029. doi:10.1016/j.conbuildmat.2019.07.338

Mailar, G., Sujay, R. N., Sreedhara, B. M., Manu, D. S., Hiremath, P., & Jayakesh, K. (2016). Investigation of concrete produced using recycled aluminium dross for hot weather concreting conditions. Resource-Efficient Technologies, 2(2), 68-80.

doi:10.1016/j.reffit.2016.06.006

Mohr, B. J., Nanko, H., & Kurtis, K. E. (2005). Durability of kraft pulp fiber–cement composites to wet/dry cycling. Cement and Concrete Composites, 27(4), 435-448. doi:10.1016/j.cemconcomp.2004.07.006

Pahuswanno, P., Chakartnarodom, P., Ineure, P., & Prakaypan, W. (2019). The influences of chemical treatment on recycled rejected fiber cement used as fillers in the fiber cement products. Journal of Metals, Materials and Minerals, 29(3), 66-70.

doi:10.14456/jmmm.2019.36

Pahuswanno, P., Chakartnarodom, P., Kongkajun, N., & Prakaypan, W. (2020). Feasibility study of using modified recycled fiber-cement for the production of high performance fiber-cement composites. Solid State Phenomena, 302, 93-99.

Sadrolodabaee, P., Claramunt, J., Ardanuy, M., & de la Fuente, A. (2021). Mechanical and durability characterization of a new textile waste micro-fiber reinforced cement composite for building applications. Case Studies in Construction Materials, 14.

doi:10.1016/j.cscm.2021.e00492

Sonprasarn, P., Chakartnarodom, P., Ineure, P., & Prakaypan, W. (2019). Effects of the chemical treatment on coal-fired bottom ash for the utilization in fiber-reinforced cement. Journal of Metals, Materials and Minerals, 29(4), 55-60.doi:10.14456/jmmm.2019.47

Sonprasarn, P., Chakartnarodom, P., Kongkajun, N., & Prakaypan, W. (2020). Microstructure and mechanical performance of fiber-reinforced cement composites made with nucleating-agent activated coal-fired power plant bottom ash. Solid State Phenomena, 302, 85-92.

Wong, H. S., Barakat, R., Alhilali, A., Saleh, M., & Cheeseman, C. R. (2015). Hydrophobic concrete using waste paper sludge ash. Cement and Concrete Research, 70, 9-20.doi:10.1016/j.cemconres.2015.01.005

Yao, X., Wang, W., Liu, M., Yao, Y., & Wu, S. (2019). Synergistic use of industrial solid waste mixtures to prepare ready-to-use lightweight porous concrete. Journal of Cleaner Production, 211, 1034-1043. doi:10.1016/j.jclepro.2018.11.252