Effect of Preparation Conditions on Crosslinking Behavior of Linseed Oil-Based Thermosetting Polymer

DOI:

https://doi.org/10.53848/ssstj.v10i2.491Keywords:

Thermosetting polymer, Epoxidized linseed oil, Fatty acid trimerAbstract

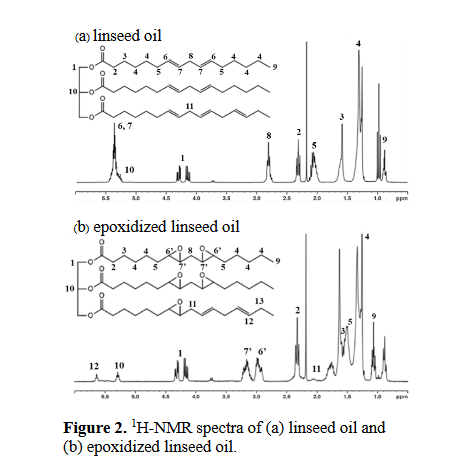

Bio-based materials have received more attention to replace materials from petroleum resources because of sustainability reason. Plant oil is one of the most interesting raw materials to produce thermosetting polymer. A crosslinking reaction between epoxidized linseed oil and vegetable oil-based crosslinkers is investigated in present study. Two types of crosslinker including fatty acid dimer and fatty acid trimer were reacted with epoxidized linseed oil. A rotational rheometer equipped with cone-and-plate geometry was used to monitor the progress of three-dimensional network formation. A curing phenomenon was illustrated by the increment in storage modulus of the reaction mixture. The trifunctional crosslinker was more effective than difunctional crosslinker for an uncatalyzed systems at the reaction temperature of 120 OC. When the crosslinking temperature of trimer-crosslinker system increased from 120 OC to 140 OC, the induction time for curing decreased around three times. The reaction between epoxidized oil and trimer acid was obviously accelerated by using 4-methyl amino pyridine as a catalyst. Increasing the catalyst content induced a monotonically reduction in induction time of curing process. The induction time of the reaction between epoxidized linseed oil and trimer acid with 2% catalyst at reaction temperature of 120 OC was only 18 minutes, which was significantly shorter than that of an uncatalyzed systems around seven times.

References

Balart, J. F., Fombuena, V., Fenollar, O., Boronat,T., & Sánchez-Nacher, L. (2016). Processing and characterization of high environmental

efficiency composites based on PLA and hazelnut shell flour (HSF) with biobased plasticizers derived from epoxidized linseed oil(ELO). Composites Part B: Engineering, 86,168-177.doi:10.1016/j.compositesb.2015.09.063

Chen, Y., Xi, Z., & Zhao, L. (2016). New bio-based polymeric thermosets synthesized by ring-opening polymerization of epoxidized soybean oil with a green curing agent. European Polymer Journal, 84(1), 435-447.doi:10.1016/j.eurpolymj.2016.08.038

Dos Santos Martini, D., Braga, B. A., & Samios, D.(2009). On the curing of linseed oil epoxidized methyl esters with different cyclic dicarboxylic anhydrides. Polymer, 50(13), 2919-2925.doi:10.1016/j.polymer.2009.03.058

Janković, M. R., Govedarica, O. M., & Sinadinović-Fišer, S. V. (2020). The epoxidation of linseed oil with in situ formed peracetic acid: A model with included influence of the oil fatty acid composition. Industrial Crops and Products,143. doi:10.1016/j.indcrop.2019.111881

Khandelwal, V., Sahoo, S. K., Kumar, A., & Manik,G. (2018). Electrically conductive green composites based on epoxidized linseed oil and polyaniline: An insight into electrical, thermal and mechanical properties. Composites Part B: Engineering, 136, 149-157. doi:10.1016/j.compositesb.2017.10.030

López Téllez, G., Vigueras-Santiago, E., & Hernández-López, S. (2009). Characterization of linseed oil epoxidized at different percentages. Superficies y Vacío, 22(1), 5-10.

Musik, M., Bartkowiak, M., & Milchert, E. (2022).Advanced methods for hydroxylation of vegetable oils, unsaturated fatty acids and their alkyl esters. Coatings, 12(1).doi:10.3390/coatings12010013

Nieto, J. F., Santiago, E. V., & López, S. H. (2021).Determination of the number of epoxides groups by FTIR-HATR and its correlation with 1H NMR in epoxidized linseed oil. Advances in Analytical Chemistry, 11(1), 1-8.doi:10.5923/j.aac.20211101.01

Qi, M., Xu, Y. J., Rao, W. H., Luo, X., Chen, L., & Wang, Y. Z. (2018). Epoxidized soybean oil cured with tannic acid for fully bio-based epoxy resin. RSC Advances, 8(47), 26948-26958. doi:10.1039/c8ra03874k

Saithai, P., Jonjanekieat, S., Chinpa, W., & Tanrattanakul, V. (2007). Preparation of epoxidized soybean oil. KMUTT Research & Development Journal, 4(1), 583-589.

Salih, A. M., Ahmad, M. B., Ibrahim, N. A., Dahlan, K. Z., Tajau, R., Mahmood, M. H., & Yunus, W. M. Z. W. (2015). Synthesis of radiation curable palm oil–based epoxy acrylate: NMR and FTIR spectroscopic investigations. Molecules, 20(8), 14191-14211. doi:10.3390/molecules200814191

Samper, M. D., Petrucci, R., Sánchez-Nacher, L., Balart, R., & Kenny, J. M. (2015). New environmentally friendly composite laminates with epoxidized linseed oil (ELO) and slate fiber fabrics. Composites Part B: Engineering, 71, 203-209. doi:10.1016/j.compositesb.2014.11.034

Singh, M., Sethi, S. K., & Manik, G. (2022).Pressure-sensitive adhesives based on acrylated epoxidized linseed oil: A computational approach. International Journal of Adhesion and Adhesives, 112. doi:10.1016/j.ijadhadh.2021.103031

Tao, Y., Fang, L., Dai, M., Wang, C., Sun, J., & Fang, Q. (2020). Sustainable alternative to bisphenol A epoxy resin: High-performance recyclable epoxy vitrimers derived from protocatechuic acid. Polymer Chemistry, 11(27), 4500-4506. doi:10.1039/d0py00545b

Thuy, N. T., & Duc, V. M. (2020). The epoxidized linseed oil as a secondary plasticizer in PVC processing. Vietnam Journal of Chemistry, 58(4), 534-539. doi:10.1002/vjch.202000023

Xia, W., Budge, S. M., & Lumsden, M. D. (2015).New 1H NMR-based technique to determine epoxide concentrations in oxidized oil. Journal of Agricultural and Food Chemistry, 63(24), 5780-5786. doi:10.1021/acs.jafc.5b01719

Zhao, W., An, L., & Wang, S. (2021). Recyclable high-performance epoxy-anhydride resins with DMP-30 as the catalyst of transesterification reactions. Polymers, 13(2).doi:10.3390/polym13020296

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Suan Sunandha Rajabhat University

This work is licensed under a Creative Commons Attribution 4.0 International License.