The Glass Produced from Recycled Soda-Lime Glass Cullet by Slip Casting

DOI:

https://doi.org/10.53848/ssstj.v10i2.553Keywords:

glass, cullet, slip casting, four-points bending test, Weibull modulusAbstract

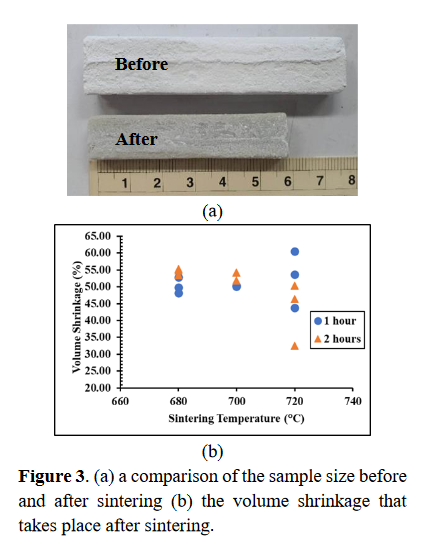

Slip casting is a ceramic processing technique which can be used to produce complex-shape ceramic object. In the present work, slip casting was applied to produce the 70 mm × 10 mm × 15 mm green samples from recycled soda-lime glass. The slip with 60% solid loading was prepared from 100 g of recycled cullet, 1 g of sodium silicate as a binder, 50 ml of DI water, and 16.7 ml of deflocculant. The deflocculant for slip casting was 0.1 wt% sodium tripolyphosphate solution. After slip casting, the samples were dried at room temperature for 3 days. Then the samples were sintered at 680, 700, and 720 °C with the soaking time of 1 and 2 hrs with 5 °C/min heating rate. The results from statistical analysis showed that there was a high variation on flexural strength which should be from the high closed porosity and high pore-size variation of the samples. Therefore, our glass produced from slip casting is not suitable for load bearing applications. However, this technique still can be used to produce other art products such as Buddha amulets.

References

Ashby, M. F. (2013). Materials and the environment (2nd ed.) (pp. 459-595). UK: Butterworth-Heinemann.

Askeland, D. R., Fulay, P. P., & Wright, W. J.(2010). The science and engineering of materials (6th ed.). USA: Cengage Learning.

Callister Jr, W. D. , & Rethwisch, D. G. ( 2014) .Materials science and engineering: An introduction ( 9th ed.) . NJ, United States: John Wiley & Sons.

Deeprasertwong, E., Ineure, P., Kongkajun, N.,Borwornkiatkaew, W., Laitila, E. A.,Chuankrerkkul, N., & Chakartnarodom, P.(2022). Properties of the glass formed from ground glass cullet via sintering. Materials Today: Proceedings, 65, 2461-2466. doi:10.1016/j.matpr.2022.06.391

Editors. (2021). Glass is the hidden gem in a carbon-neutral future. Nature, 599, 7-8.doi:10.1038/d41586-021-02992-8

Hu, Y., & Miao, X. (2004). Comparison of hydroxyapatite ceramics and hydroxyapatite/borosilicate glass composites prepared by slip casting. Ceramics International, 30(7), 1787-1791. doi:10.1016/j.ceramint.2003.12.119

Marghussian, V. K., & Geramian, M. J. (1999).Fabrication of cordierite glass ceramics by slip casting of glass powders. British Ceramic Transactions, 98(3), 133-140. doi:10.1179/096797899680345

Mei, S., Yang, J., & Ferreira, J. M. F. (2003).Comparison of dispersants performance in slip casting of cordierite-based glass- ceramics. Ceramics International, 29(7),785-791. doi:10.1016/S0272-8842(02)00231-6

Tempelman, E., Shercliff, H., & van Eyben, B. N.(2014). Manufacturing and design (pp.227-250). UK: Butterworth-Heinemann

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Suan Sunandha Rajabhat University

This work is licensed under a Creative Commons Attribution 4.0 International License.