Oxidation Behavior of Nanostructure CrAlN Thin Films

DOI:

https://doi.org/10.53848/ssstj.v12i1.874Keywords:

Oxidation behavior, CrAlN, Thin film, Sputtering, Alloy targetAbstract

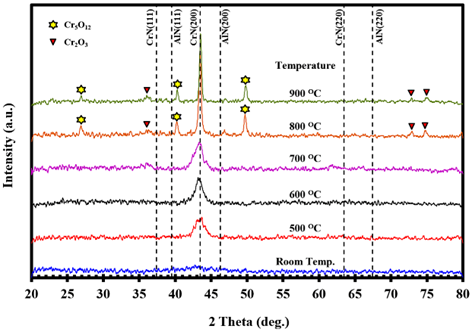

In this research, the nanostructure chromium aluminium nitride (CrAlN) thin films were prepared on silicon (100) substrate by reactive DC magnetron sputtering technique with Cr-Al alloy target and then annealing in air at different temperatures (500 - 900 °C) to investigate the oxidation behavior. The films' oxidation rate and oxidation activation energy were also calculated using parabolic relations and the Arrhenius equation. The X-ray diffraction (XRD) indicated that a solid solution CrAlN structure was found for the as-deposited thin film whereas the mixed oxide phase of Cr2O3 and Cr5O12 structures were discovered in the XRD spectra upon oxidation temperature at 800 °C. The XRD patterns were verified by the Energy dispersive X-ray spectroscopy (EDS) examination, which demonstrated the obvious increase of oxygen concentration at oxidation temperature from 800 °C due to the oxidation mechanism. The oxidation behavior was also confirmed by field-emission scanning electron microscopy (FE-SEM) analysis which the grain aggregation was observed while the cross-sectional microstructure of the thin films revealed that a very thin dense oxide layer was formed on the CrAlN layer. The oxide thickness increased from 648 nm to 1044 nm with increasing annealing temperature. The thin films began oxidizing above 800 °C, resulting in a porous structure. It was discovered that the as-deposited thin film exhibited a high-temperature oxidation resistance at 800 °C. The oxidation rate increased from 1.43 × 10-13 to 3.78 × 10-13 cm/s2 and was obtained from an annealing temperature of 800 °C. The oxidation activation energy calculated from the Arrhenius plot was 99.85 kJ/mol. The nanoindentation technique also reported that the hardness of the films decreased from 15.92 to 0.03 GPa through the annealing temperature.

References

Alaksanasuwan, S., Buranawong, A., & Witit-anun, N. (2022). Structural and oxidation behavior of nanocomposite TiCrN thin films. Suan Sunandha Science and Technology Journal, 9(2). 53-62.

https://doi.org/10.53848/ssstj.v9i2.234

Alaksanasuwan, S., & Witit-anun, N. (2023). Synthesis and characterization of TiN thin films by DC reactive magnetron sputtering. Suan Sunandha Science and Technology Journal, 10(2). 205-212.

https://doi.org/10.53848/ssstj.v10i2.353

Anders, A. (2010). A structure zone diagram including plasma-based deposition and ion etching. Thin Solid Films, 518(15), 4087-4090. https://doi.org/10.1016/j.tsf.2009.10.145

Anwar, S., Anwar, S., Priyadarshini, B., & Sankar, R. S. (2022). Evaluation of structural and mechanical properties of CrAlN single layer coating deposited by reactive magnetron sputtering. Materials Chemistry and Physics, 292, 126873. https://doi.org/10.1016/j.matchemphys.2022.126873

Banakh, O., Schmid, P. E., Sanjines, R., & Levy, F. (2003). High-temperature oxidation resistance of Cr1−xAlxN thin films deposited by reactive magnetron sputtering. Surface and Coatings Technology, 163-164, 57-61. https://doi.org/10.1016/S0257-8972(02)00589-3

Barshilia, H. C., Selvakumar, N., Deepthi, B., & Rajam, K. S. (2006). A comparative study of reactive direct current magnetron sputtered CrAlN and CrN coatings. Surface and Coatings Technology, 201(6), 2193-2201. https://doi.org/10.1016/j.surfcoat.2006.03.037

Buranawong, A., & Witit-anun, N. (2022). Oxidation behavior of nanostructure sputtered titanium nitride thin films. Current Applied Science and Technology, 22(6), 1-11. https://doi.org/10.55003/cast.2022.06.22.015

Chim, Y. C., Ding X. Z., Zeng, X. T., & Zhang, S. (2009). Oxidation resistance of TiN, CrN, TiAlN and CrAlN coatings deposited by lateral rotating cathode arc. Thin Solid Films, 517(17), 4845-4849.

https://doi:10.1016/j.tsf.2009.03.038

Drnovšek, A., Kukuruzovic, D., Terk, P., Miletic, A., Cekada, M., Panjan, M., & Panjan, P. (2023). Microstructural, mechanical and oxidation resistance of nanolayer sputter-deposited CrAlN hard coatings. Coatings, 13(12), 2096. https://doi.org/10.3390/coatings13122096

He, X.-M., Baker, N., Kehler, B. A., Walter, K. C., Nastasi, M., & Nakamura, Y. (2000). Structure, hardness, and tribological properties of reactive magnetron sputtered chromium nitride films. Journal of Vacuum Science & Technology A, 18(1), 30-36.

He, Y., Gao, K., Yang, H., Pang, X., & Volinsky, A. A. (2021). Nitrogen effects on structure, mechanical and thermal fracture properties of CrN films. Ceramics International, 47(21), 30729-30740.

https://doi.org/10.1016/j.ceramint.2021.07.252

Kang, Q., Wang, G., Liu, Q., Sui, X., Liu, Y., Chen, Y., Luo, S., & Li, Z. (2021). Investigation for oxidation mechanism of CrN: A combination of DFT and ab initio molecular dynamics study. Journal of Alloys and Compounds, 885, 160940. https://doi.org/10.1016/j.jallcom.2021.160940

Kayani, A., Buchanan, T. L., Kopczyk, M., Collins, C., Lucas, J., Lund, K., Hutchison, R., Gannon, P. E., Deibert, M. C., Smith, R. J., Choi, D.-S., & Gorokhovsky, V. I. (2006). Oxidation resistance of magnetron-sputtered CrAlN coatings on 430 steel at 800°C. Surface and Coatings Technology, 201(7), 4460-4466.

https://doi.org/10.1016/j.surfcoat.2006.08.049

Khamseh, S., & Araghi, H. (2016). A study of the oxidation behavior of CrN and CrZrN ceramic thin films prepared in a magnetron sputtering system. Ceramics International, 42(8), 9988-9994.

https://doi.org/10.1016/j.ceramint.2016.03.101

Khamseh, S, Nose, M., Kawabata, T., Matsuda, K., & Ikeno, S. (2010). Oxidation resistance of CrAIN films with different microstructures prepared by pulsed DC balanced magnetron sputtering system. Materials Transactions, 51(2), 271-276. https://doi.org/10.2320/matertrans.MC200912

Khamseh, S, Nose, M., Kawabata, T., Nagae, T., Matsuda, K., & Ikeno, S. (2010). A comparative study of CrAlN films synthesized by dc and pulsed dc reactive magnetron facing target sputtering system with different pulse frequencies. Journal of Alloys and Compounds, 508(1), 191-195.

https://doi.org/10.1016/j.jallcom.2010.08.042

Kim, S., Yoon, H. W., Moon, K., & Lee, C. S. (2021). Mechanical and friction behavior of sputtered

Mo–Cu–(N) coatings under various N2 gas flow using a multicomponent single alloy target. Surface and Coatings Technology, 412, 127060. https://doi.org/10.1016/j.surfcoat.2021.127060

Lin, J., Mishra, B., Moore, J. J., & Sproul, W. D. (2008). A study of the oxidation behavior of CrN and CrAlN thin films in air using DSC and TGA analyses. Surface and Coatings Technology, 202(14), 3272-3283.

https://doi.org/10.1016/j.surfcoat.2007.11.037

Liu, J., Hao, Z., Cui, Z., Ma, D., Lu, J., Cui, Y., Li, C., Liu, W., Xie, S., Hu, P. Huang, P., Bai, G., & Yun, D. (2021). Oxidation behavior, thermal stability, and the coating/substrate interface evolution of CrN-coated Zircaloy under high-temperature steam. Corrosion Science, 185, 109416.

https://doi.org/10.1016/j.corsci.2021.109416

Mayrhofer, P. H., Willmann, H., & Reiter, A. E. (2008). Structure and phase evolution of Cr–Al–N coatings during annealing. Surface and Coatings Technology, 202(20), 4935-4938.

https://doi.org/10.1016/j.surfcoat.2008.04.075

Priyadarshini, B., Anwar, S., & Anwar, S. (2023). Substrate temperature: A governing factor for the structural, mechanical and chemical properties of sputtered CrAlN ternary coating. Thin Solid Films, 771, 139788.

https://doi.org/10.1016/j.tsf.2023.139788

Qi, Z. B., Liu, B., Wu, Z. T., Zhu, F. P., Wang, Z. C., & Wu, C. H. (2013). A comparative study of the oxidation behavior of Cr2N and CrN coatings. Thin Solid Films, 544, 515-520.

https://doi.org/10.1016/j.tsf.2013.01.031

Qu, S.-J., Huang, S.-Q., Guo, C.-Q., Dai, M.-J., Lin, S., Shi, Q., Su, Y.-F., Wei, C.-B., Yang, Z., & Chekan, N. M. (2023). Chromium arc plasma characterization, structure and properties of CrN coatings prepared by vacuum arc evaporation. Vacuum, 209, 111796. https://doi.org/10.1016/j.vacuum.2022.111796

Tillmann, W., Dias, N. F. L., & Stangier, D. (2018). Effect of Hf on the microstructure, mechanical properties, and oxidation behavior of sputtered CrAlN films. Vacuum, 154, 208-213.

https://doi.org/10.1016/j.vacuum.2018.05.015

Wang, L, & Nie, X. (2014). Effect of annealing temperature on tribological properties and material transfer phenomena of CrN and CrAlN coatings. Journal of Materials Engineering and Performance, 23, 560-571.

https://doi.org/10.1007/s11665-013-0748-z

Xingrun, R., Qinying, Z., Zhu, H., Wei, S., Jiangao, Y., & Hao, C. (2018). Microstructure and tribological properties of CrN films deposited by direct current magnetron sputtering. Rare Metal Materials and Engineering, 47(8), 2283-2289. https://doi.org/10.1016/S1875-5372(18)30180-2

Xingrun, R., Zhu, H., Meixi, L., Jiangao, Y., & Hao, C. (2018). Comparison of microstructure and tribological behaviors of CrAlN and CrN film deposited by DC magnetron sputtering. Rare Metal Materials and Engineering, 47(4), 1100-1106. https://doi.org/10.1016/S1875-5372(18)30127-9.

Zhang, M, Lin, G., Lu, G., Dong, C., & Kim, K. H. (2008). High-temperature oxidation resistant (Cr, Al)N films synthesized using pulsed bias arc ion plating. Applied Surface Science, 254(22), 7149-7154.

https://doi.org/10.1016/j.apsusc.2008.05.293

Zhu, M., Li, M., & Zhou, Y. (2006). Oxidation resistance of Cr1−xAlxN (0.18 ≤ x ≤ 0.47) coatings on K38G superalloy at 1000–1100°C in air. Surface and Coatings Technology, 201(6), 2878-2886.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Suan Sunandha Rajabhat University

This work is licensed under a Creative Commons Attribution 4.0 International License.