Reinforcing Fiber-Cement Composites for Flooring with Fibers from Low-Grade Coal Fly Ash

DOI:

https://doi.org/10.53848/ssstj.v12i2.973Keywords:

Mae Moh, Ash, Fiber, Composites, Building materials, SustainabilityAbstract

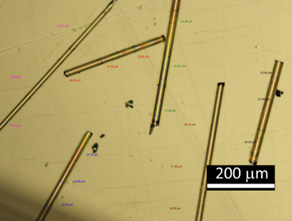

Low-grade coal fly ash (LGFA) is characterized as fly ash with a sulfur trioxide (SO3) content exceeding 5%, according to the ASTM C618 standard. The fibers derived from this LGFA, combined with dolomite and basalt, served as the reinforcing phase in fiber-reinforced cement composite (FRCC) samples designed for flooring systems. These FRCC samples were manufactured using the filter pressing method and subjected to air curing for 7 and 28 days. Following the curing process, a three-point bend test was conducted to assess their modulus of rupture (MOR) and modulus of elasticity (MOE), an impact test was performed to measure their impact strength, and their bulk density was determined using Archimedes method.Low-grade coal fly ash (LGFA), as defined by ASTM C618, is fly ash with a sulfur trioxide (SO₃) content exceeding 5%. This LGFA can be used with dolomite and basalt to produce fibers for fiber-reinforced cement composite (FRCC) specifically designed for flooring systems replacing the more expensive PVA fibers. Specimens of the FRCC flooring were fabricated using the filter-pressing method and cured in air for 7 and 28 days. Following curing, the modulus of rupture (MOR) and modulus of elasticity (MOE) were determined from three-point bend tests. The results demonstrated that both MOR and MOE of the FRCC specimens increased with longer curing durations. While statistical analysis revealed no significant correlation between LGFA fiber content and MOR, a positive linear relationship was observed between LGFA fiber content and the MOE, indicating an enhanced elastic modulus with greater LGFA fiber content. Both values meet or exceed the ASTM standard required for flooring boards while making use of a waste product at a lower manufacturing cost.

References

Askeland, D. R., Fulay, P. P., & Wright, W. J. (2010). The science and engineering of materials (6th ed.). Cengage Learning.

ASTM International. (2016). ASTM C1185 Standard test methods for sampling and testing non-asbestos fiber-cement flat sheet, roofing and siding shingles, and clapboards. West Conshohocken, PA, USA.

Chakartnarodom, P., Polsilapa, S., Prakaypan, W., Ineure, P., Chuankrerkkul, N., Laitila, E. A., & Kongkajun, N. (2024). Upcycling low-grade coal fly ash for the production of fly ash fibers and their applications in fiber-reinforced cement composites. Construction and Building Materials, 414, 134880. https://doi.org/10.1016/j.conbuildmat.2024.134880

Devore, J. L. (2012). Probability and statistics for engineering and the sciences (8th ed.). Brooks/Cole, Cengage Learning.

EGAT. (2021). Unseen EGAT by ENGY. https://www.egat.co.th/home/unseen-egat-by-engy-

EGAT. (2025). The proportion of fuel used for electricity generation in the EGAT system. https://www.egat.co.th/home/statistics-fuel-usage/

Erol, M. M., Küçükbayrak, S., & Ersoy-Meriçboyu, A. (2006). The recycling of the coal fly ash in glass production. Journal of Environmental Science and Health, Part A, 41(9), 1921–1929.https://doi.org/10.1080/10934520600779208

Meyers, M. A., & Chawla, K. K. (2009). Mechanical behavior of materials. Cambridge University Press.

Nath, P., Sarker, P. K., & Biswas, W. K. (2018). Effect of fly ash on the service life, carbon footprint and embodied energy of high strength concrete in the marine environment. Energy and Buildings, 158, 1694–1702. https://doi.org/10.1016/j.enbuild.2017.12.011

Selvaraj, S., & Chan, T.-M. (2024). Recommendations for implementing circular economy in construction: Direct reuse of steel structures. Journal of Constructional Steel Research, 214, 108439. https://doi.org/10.1016/j.jcsr.2023.108439

Suraneni, P., Burris, L., Shearer, C. R., & Hooton, R. D. (2021). ASTM C618 Fly ash specification: Comparison with other specifications, shortcomings, and solutions. ACI Materials Journal, 118(1), 157–167. https://doi.org/10.14359/51725994

The British Standard Institution. (2014). BS 6920 Section 2.6 Suitability of non-metallic products for use in contact with water intended for human consumption with regard to their effect onthe quality of the water. BSI.

The British Standards Institution. (2018). BS EN 12467 Fibre-cement flat sheets - Product specification and test methods. BSI.

Walpole, R. E., Myers, R. H., Myers, S. L., & Ye, K. (2012). Probability & statistics for engineers & scientists (9th ed.). Prentice Hall.

Zhang, J., Wen, X., & Cheng, F. (2021). Preparation, thermal stability and mechanical properties of inorganic continuous fibers produced from fly ash and magnesium slag. Waste Management,120,156–163. https://doi.org/10.1016/j.wasman.2020.11.021

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Suan Sunandha Rajabhat University

This work is licensed under a Creative Commons Attribution 4.0 International License.