Barrier and Seal Properties of Reactive Blending of Poly(butylene succinate) Based Blends

DOI:

https://doi.org/10.53848/ssstj.v9i2.231Keywords:

Poly(butylene succinate), Poly(hydroxybutyrate-co-hydroxyvalerate), Reactive blending film, Barrier properties, Peelable filmAbstract

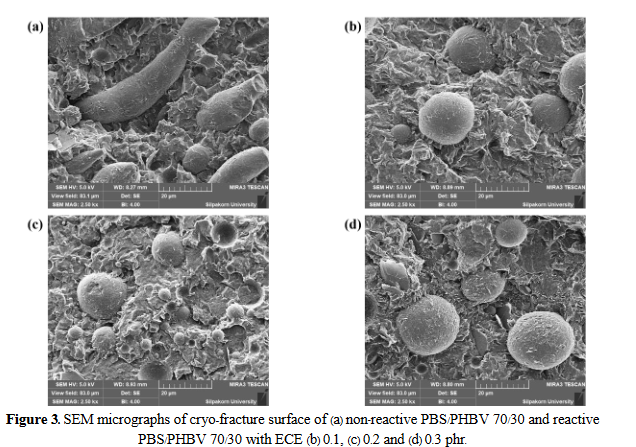

Poly Butylene Succinate (PBS) is one of the biodegradable polymers with good physical properties but its barrier properties such as the oxygen barrier are poor. The aim of this study was to investigate the barrier and seal properties of PBS by blending with biodegradable poly hydroxybutyrate-co-hydroxyvalerate (PHBV). PBS and PHBV (80/20 and 70/30 %w/w) with and without reactive agents were prepared using an internal mixer. Film specimens of 100 micrometers in thickness were prepared using compression molding. The morphology, barrier properties and peel-seal strength were investigated. Morphological observations using scanning electron microscope (SEM) showed an improved dispersion of PHBV in the blends after adding the reactive agents. The oxygen barrier and water vapor barrier were determined using ASTM D3985 and ASTM E96, respectively. The results showed that the addition of PHBV into the blend films led to lower OTR and WVTR when compared to the neat PBS. The addition of reactive agents can further improve the OTR and WVTR of PBS/PHBV blends due to the compact and dense structure of the films. Peel–seal behavior of the films was examined by the different sealing temperatures, which determined the failure mechanism after peeling. The blend films with reactive agents after sealing temperature between 105 and 115°C were peeled from the substrate with adhesive and cohesive failures showing the easy peel mode.

References

Chinga-Carrasco, G., & Syverud, K. (2012). On the structure and oxygen transmission rate of biodegradable cellulose nanobarriers. Nanoscale Research Letters, 7(1), 192. doi:10.1186/1556-276X-7-192

Cunha, M., Fernandes, B., Covas, J. A., Vicente, A. A., & Hilliou, L. (2016). Film blowing of PHBV blends and PHBV-based multilayers for the production of biodegradable packages. Journal of Applied Polymer Science, 133(2). doi:10.1002/app.42165

Diaz, C., Pao, H. Y., & Kim, S. (2016). Film performance of poly (lactic acid) blends for packaging applications. Journal of Applied Packaging Research, 8, 4.

Liewchirakorn, P., Aht-ong, D., & Chinsirikul, W. (2017). Practical approach in developing desirable peel-seal and clear lidding films based on poly (lactic acid) and poly (butylene adipate-co-terephthalate) blends. Packaging Technology and Science, 31. doi:10.1002/pts.2321

Ma, P., Hristova-Bogaerds, D. G., Lemstra, P. J., Zhang, Y., & Wang, S. (2012). Toughening

of PHBV/PBS and PHB/PBS blends via in situ compatibilization using dicumyl peroxide as a free-radical grafting initiator. Macromolecular Materials and Engineering, 297(5), 402-410. doi:10.1002/mame.201100224

Muthuraj, R., Misra, M., & Mohanty, A. (2017). Biodegradable compatibilized polymer blends for packaging applications: A literature review. Journal of Applied Polymer Science, 135. doi:10.1002/app.45726

Nanthananon, P., Seadan, M., Pivsa-Art, S., Hiroyuki, H., & Suttiruengwong, S. (2017). Biodegradable polyesters reinforced with eucalyptus fiber: Effect of reactive agents. AIP Conference Proceedings, 1914(1), 070012. doi:10.1063/1.5016739

Nuchanong, P., Seadan, M., Khankrua, R., & Suttiruengwong, S. (2021). Thermal

stability enhancement of poly (hydroxybutyrate-co-hydroxyvalerate) through in situ reaction. Designed Monomers and Polymers, 24(1), 113-124. doi:10.1080/15685551.2021.1914406

Phua, Y. J., Pegoretti, A., Medeiros Araujo, T., & Mohd Ishak, Z. A. (2015). Mechanical and thermal properties of poly(butylene succinate)/poly(3-hydroxybutyrate-co-3-hydroxyvalerate) biodegradable blends. Journal of Applied Polymer Science, 132(47). doi:10.1002/app.42815

Phuangmali, I., Seadan, M., Khankrua, R., & Suttiruengwong, S. (2021). Reactive compatibilization of poly (hydroxybutyrateco-hydroxyvalerate)/polyvinyl alcohol blends. Polymer-Plastics Technology and Materials, 60(13), 1461-1473. doi:10.1080/25740881.2021.1918162

Rodriguez-Uribe, A., Wang, T., Pal, A. K., Wu, F., Mohanty, A. K., & Misra, M. (2021). Injection moldable hybrid sustainable composites of BioPBS and PHBV reinforced with talc and starch as potential alternatives to single-use plastic packaging. Composites Part C: Open Access, 6, 100201. doi:10.1016/j.jcomc.2021.100201

Siracusa, V., Lotti, N., Munari, A., & Dalla Rosa, M. (2015). Poly (butylene succinate) and poly (butylene succinate-co-adipate) for food packaging applications: Gas barrier properties after stressed treatments. Polymer Degradation and Stability, 119, 35-45. doi:10.1016/j.polymdegradstab.2015.04.026

Wu, F., Misra, M., & Mohanty, A. K. (2021). Challenges and new opportunities on barrier performance of biodegradable polymers for sustainable packaging. Progress in Polymer Science, 117. doi:10.1016/j.progpolymsci.2021.101395

Xu, J. (2015). Biobased nanocomposites for packaging applications-synthesis using melt extrusion of poly (lactic acid), poly (butylene succinate) and/or starch blended with natural nanofillers (Master’s thesis). Kansas State University. Retrieved from http://hdl.handle.net/2097/20561

Yang, Z., Xin, C., Mughal, W., Li, X., & He, Y. (2017). High-melt-elasticity poly (ethylene terephthalate) produced by reactive extrusion with a multi-functional epoxide for foaming. Journal of Applied Polymer Science, 135, 45805. doi:10.1002/app.45805

Zembouai, I., Kaci, M., Bruzaud, S., Benhamida, A., Corre, Y.-M., & Grohens, Y. (2013). A study of morphological, thermal, rheological and barrier properties of poly (3-hydroxybutyrate-co-3-hydroxyvalerate)/polylactide blends prepared by melt mixing. Polymer Testing, 32(5), 842-851. doi:10.1016/j.polymertesting.2013.04.004

Zhang, J., Manias, E., Polizos, G., Huh, J.-Y., Ophir, A., Songtipya, P., & Jimenez-Gasco, M. d. M. (2009). Tailored polyethylene nanocomposite sealants: Broad-range peelable heat-seals through designed filler/polymer interfaces. Journal of Adhesion Science and Technology, 23(5), 709-737. doi:10.1163/156856108X379182