Structural and Oxidation Behavior of Nanocomposite TiCrN Thin Films

DOI:

https://doi.org/10.53848/ssstj.v9i2.234Keywords:

TiCrN thin film, Oxidation, Reactive sputtering, Mosaic targetAbstract

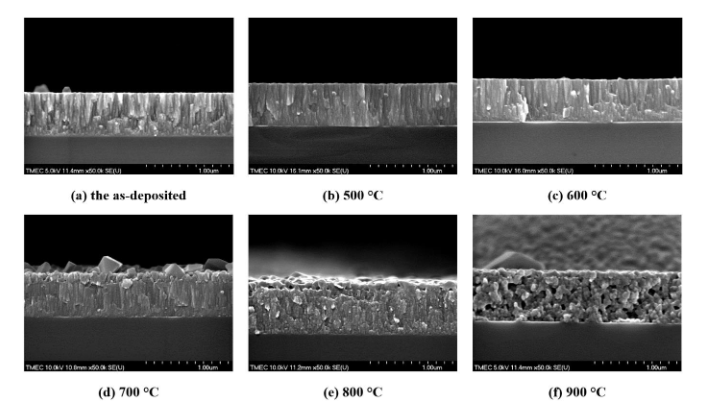

The structural and oxidation behavior of nanocomposite titanium chromium nitride (TiCrN) thin films has been investigated by using x-ray diffraction (XRD), energy dispersive x-ray spectroscopy (EDS), and field emission scanning electron microscopy (FE-SEM). The TiCrN thin films were deposited on Si substrates by using the reactive DC magnetron sputtering technique from the Ti-Cr mosaic target. After that, the as-deposited thin films were annealed in the air at 500 - 900°C for 2 h. The XRD results showed that the formation oxidation of anataseTiO2, rutile-TiO2, and Cr2O3 which diffraction peak appear from 500°C. The relative intensity of these oxide peaks varied with the annealed temperatures. By observing from FE-SEM, the aggregation of the grain increased with the annealing temperature. The cross-sectional results showed that the thin dense oxide overlayer occurred at 700°C and the oxide thickness increased gradually with the annealing temperature. Meanwhile, underneath the TiCrN grain grew above 700°C and become more void structure after annealing at 700°C. The dramatically increase of the oxygen content was found at 700°C and the evolution of Ti, Cr, N, and O with different elements compositions at various annealing temperatures were investigated from the EDS technique. The oxide layer obviously grows inward indicating the oxidation of TiCrN thin films belongs to inward oxidation. The oxidation rate of the films was increased with the increase of annealing temperature. The activation energy of the oxidation as evaluated by the Arrhenius-type relation was 168 kJ/mol.

References

Alaksanasuwan, S., Buranawong, A., & Witit-Anun, N. (2020). Effect of sputtering current on the structure of TiCrN thin films prepared from mosaic target by reactive DC magnetron sputtering. Applied Mechanics and Materials, 901, 37-42. doi:10.4028/www.scientific.net/AMM.901.37

Alberdi, A., Marin, M., Diaz, B., Sanchez, O., & Galindo, R. E. (2007). Wear resistance of titanium-aluminium-chromium-nitride nanocomposite thin films. Vacuum, 81, 1453-1456. doi:10.1016/j.vacuum.2007.04.024

Aliaj, F., Syla, N., Oettel, H., & Dilo, T. (2016). Thermal treatment in air of direct current (DC) magnetron sputtered TiN coatings. Scientific Research and Essays, 11(21), 230-238. doi:10.5897/SRE2016.6456

Chang, Y.-Y., Yang, S.-J., & Wang, D.-Y. (2007). Characterization of TiCr(C,N)/amorphous carbon coatings synthesized by a cathodic arc deposition process. Thin Solid Films, 515, 4722-4726. doi:10.1016/j.tsf.2006.11.028

Chen, H. Y., & Lu, F. H. (2006). Oxidation behavior of chromium nitride films. Thin Solid Films, 515, 2179-2184. doi:10.1016/j.tsf.2006.06.039

Chen, S., Luo, D., & Zhao, G. (2013). Investigation of the properties of TixCr1-xN coatings prepared by cathodic arc deposition. Physics Procedia, 50, 163-168. doi:10.1016/j.phpro.2013.11.027

Chim, Y. C., Ding X. Z., Zeng, X. T., & Zhang, S. (2009). Oxidation resistance of TiN, CrN, TiAlN and CrAlN coatings deposited by lateral rotating cathode arc. Thin Solid Films, 517, 4845-4849. doi:10.1016/j.tsf.2009.03.038

Choi, H. S., Han, D. H., Hong, W. H., & Lee, J. J. (2009). (Titanium, chromium) nitride coatings for bipolar plate of polymer electrolyte membrane fuel cell. Journal of Power Sources, 189, 966-971. doi:10.1016/j.jpowsour.2008.12.060

Golosov, D. A., Melnikov, S. N., & Dostanko, A. P. (2012). Calculation of the elemental composition of thin films deposited by magnetron sputtering of mosaic targets. Surface Engineering and Applied Electrochemistry, 48, 52-59. doi:10.3103/S1068375512010073

Jafari, A., Ghoranneviss, Z., Solar Elahi, A., Ghoranneviss, M., Fasihi Yazdi, N., & Rezaei, A. (2014). Effects of annealing on TiN thin film growth by DC magnetron sputtering. Advances in Mechanical Engineering, 2014, 1-6. doi:10.1155/2014/373847

Komarov, F. F., Konstantinov, V. M., Kovalchuk, A. V., Konstantinov S. V., & Tkachenko, H. A. (2016). The effect of steel substrate prehardening on structural, mechanical, and tribological properties of magnetron sputtered TiN and TiAlN coating. Wear, 352-353, 92-101. doi:10.1016/j.wear.2016.02.007

Krzanowski, J. E., & Foley, D. J. (2014). The effect of Cr content on the oxidation behavior of TiCr-N films. Coatings, 4, 308-319. doi:10.3390/coatings4020308

Mayrhofer, P. H., Willmann, H., & Mitterer, C. (2001). Oxidation kinetics of sputtered Cr-N hard coatings. Surface and Coatings Technology, 146-147, 222-228.doi:10.1016/s0257-8972(01)01471-2

Otani, Y., & Hofmann, S. (1996). High temperature oxidation behaviour of (Ti1-xCrx)N coatings.

Thin Solid Films, 287, 188-192. doi:10.1016/s0040-6090(96)08789-5

Paksunchai, C., Denchitcharoen, S., Chaiyakun, S., & Limsuwan, P. (2012). Effect of sputtering current on structure and morphology of (Ti1-xCrx)N thin films deposited by reactive unbalanced magnetron co-sputtering. Procedia Engineering, 32, 875-881. doi:10.1016/j.proeng.2012.02.026

Qi, Z. B., Liu, B., Wu, Z. T., Zhu, F. P., Wang, Z. C., & Wu, C. H. (2013). A comparative study of the oxidation behavior of Cr2N and CrN coatings. Thin Solid Films, 544, 515-520. doi:10.1016/j.tsf.2013.01.031

Rizzo A., Mirenghi, L., Massaro, M., Galietti, U., Capodieci, L., Terzi, R., … Valerini, D. (2013). Improved properties of TiAlN coatings through the multilayer structure. Surface and Coatings Technology, 235, 475-483. doi:10.1016/j.surfcoat.2013.08.006

Santecchia, E., Hamouda, A. M. S., Musharavati, F., Zalnezhad, E., Cabibbo, M., & Spigarelli, S. (2015). Wear resistance investigation of titanium nitride-based coatings. Ceramics International, 41, 10349-10379. doi:10.1016/j.ceramint.2015.04.152

Solis-Pomar, F., Nápoles, O., Vázquez Robaina, O., Gutierrez-Lazos, C., Fundora, A., Colin, A., … Melendrez, M. F. (2016). Preparation and characterization of nanostructured titanium nitride thin films at room temperature. Ceramics International, 42(6), 7571-7575. doi:10.1016/j.ceramint.2016.01.164

Thampi, V. V. A., Bendavid, A., & Subramanian, B. (2016). Nanostructured TiCrN thin films by pulsed magnetron sputtering for cutting tool applications. Ceramics International, 42,

-9948. doi:10.1016/j.ceramint.2016.03.095

Uglov, V. V., Anishchik, V. M., Zlotski, S. V., Abadias, G., & Dub, S. N. (2005). Stress and mechanical properties of Ti-Cr-N gradient coatings deposited by vacuum arc. Surface and Coatings Technology, 200, 178-181. doi:10.1016/j.surfcoat.2005.02.136

Vishnyakov, V. M., Bachurin, V. I., Minnebaev, K. F., Valizadeh, R., Teer, D. G., Colligon, J. S., … Yurasova, V. E. (2006). Ion assisted deposition of titanium chromium nitride. Thin Solid Films, 497, 189-195. doi:10.1016/j.tsf.2005.05.005

Wang, F., Wu, M. Z., Wang, Y. Y., Yu, Y. M., Wu, X. M., & Zhuge, L. J. (2013). Influence of thickness and annealing temperature on the electrical, optical and structural properties of AZO thin films. Vacuum, 89, 127-131. doi:10.1016/j.vacuum.2012.02.040

Wolfe, D. E., Gabriel, B. M., & Reedy, M. W. (2011). Nanolayer (Ti,Cr)N coatings for hard particle erosion resistance. Surface and Coatings Technology, 205, 4569-4576. doi:10.1016/j.surfcoat.2011.03.121