Effect of Wet Spinning Parameters on Bamboo Cellulose Nanofiber Filament Preparation

DOI:

https://doi.org/10.53848/ssstj.v9i2.238Keywords:

Cellulose nanofibers, Bamboo fibers, Wet spinning, MonofilamentAbstract

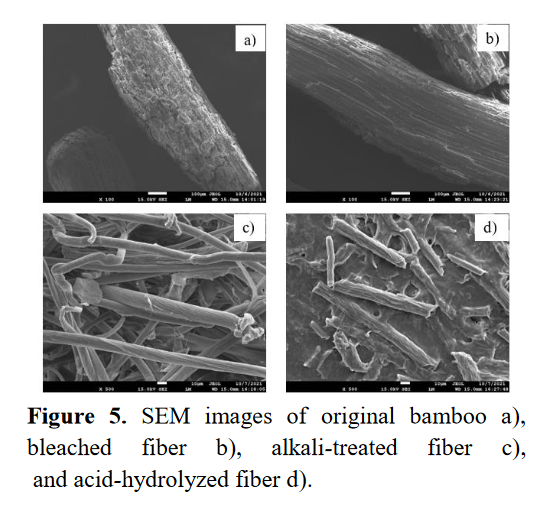

Cellulose nanofibers (CNF) are materials synthesized from wood-based fibers having excellent mechanical properties due to their high crystallinity. In this research, the cellulose nanofibers were synthesized from bamboo fibers, as the abundant natural fibers available worldwide. The cellulose nanofibers had been synthesized using chemical processes of bleaching with acetic acid and sodium chloride, followed by alkaline treatment with sodium hydroxide, and acid hydrolysis with sulfuric acid combined with mechanical process in ultrasonic bath. Isolation of nanocellulose from bamboo scrap raw material was confirmed by different analysis methods. The morphology of CNF was characterized by using a scanning electron microscope (SEM). Fourier transform infrared spectrometer (FT-IR) and X-Ray Diffractometer (XRD) examined chemical structure and identified the crystallinity of nanocellulose materials. The monofilament of cellulose nanofibers was prepared by using a wet spinning process. The effects of coagulating solvent, water, methanol, acetone, and calcium chloride (CaCl2) on monofilament formation were studied. Morphology study of CNF monofilament was carried out using a digital camera to observe the spinnability of the monofilament and the relationship with wet spinning process conditions. The thermal properties of the nanocellulose spun in methanol and acetone as coagulation solvent were analyzed by differential scanning calorimeter (DSC) and thermogravimetric analysis (TGA). Also, the measuring of degradation temperature of nanocellulose spun compared with the nanocellulose extracted.

References

Abdul Khalil, H. P. S., Bhat, I. U. H., Jawaid, M, Zaidon, A., Hermawan, D, & Hadi, Y. S. (2012). Bamboo fibre reinforced biocomposites: A review. Materials & Design, 42, 353-368. doi:10.1016/j.matdes.2012.06.015

Benini, K. C. C. C., Voorwald, H. J. C., Cioffi, M. O. H., Rezende, M. C., & Arantes, V. (2018). Preparation of nanocellulose from Imperata brasiliensis grass using Taguchi method. Carbohydrate Polymers, 192, 337-346. doi:10.1016/j.carbpol.2018.03.055

Chaichi, M., Hashemi, M., Badii, F., & Mohammadi, A. (2017). Preparation and characterization of a novel bionanocomposite edible film based on pectin and crystalline nanocellulose. Carbohydrate Polymers, 157, 167-175. doi:10.1016/j.carbpol.2016.09.062

Geng, L., Chen, B., Peng, X., & Kuang, T. (2017). Strength and modulus improvement of wetspun cellulose I filaments by sequential physical and chemical cross-linking. Materials & Design, 136, 45-53. doi:10.1016/j.matdes.2017.09.054

Gong, J., Li, J., Xu, J., Xiang, Z., & Mo, L. (2017). Research on cellulose nanocrystals produced from cellulose sources with various polymorphs. RSC Advances, 7, 33486-33493. doi:10.1039/C7RA06222B

Gupta, B., Revagade, N., Anjum, N., Atthoff, B., & Hilborn, J. (2006). Preparation of poly (lactic acid) fiber by dry‐jet‐wet‐spinning. I. Influence of draw ratio on fiber properties. Journal of Applied Polymer Science, 100(2), 1239-1246. doi:10.1002/app.23497

Jiang, S., Wei, Y., Hu, Z., Ge, S., Yang, H., & Peng, W. (2020). Potential application of bamboo powder in PBS bamboo plastic composites. Journal of King Saud University - Science,

, 1130-1134. doi:10.1016/j.jksus.2019.10.014

Joy, J., Jose, C., Varanasi, S. B., Mathew, P., Thomas, S., & Pilla, S. (2016). Preparation and characterization of poly (butylene succinate) bionanocomposites reinforced with cellulose nanofiber extracted from Helicteres isora plant. Journal of Renewable Materials, 4, 351-364. doi:10.7569/JRM.2016.634128

Kafy, A., Kim, H. C., Zhai, L., Kim, J. W., Hai, L. V., Kang, T. J., & Kim, J. (2017). Cellulose long fibers fabricated from cellulose nanofibers and its strong and tough characteristics. Scientific Reports, 7, 17683. doi:10.1038/s41598-017-17713-3

Kwak, H. W., Lee, H., Lee, M. E., & Jin, H.-J. (2018). Facile and green fabrication of silk sericin films reinforced with bambooderived cellulose nanofibrils. Journal of Cleaner Production, 200, 1034-1042. doi:10.1016/j.jclepro.2018.07.289

Liminana, P., Garcia-Sanoguera, D., QuilesCarrillo, L., Balart, R., & Montanes, N. (2018). Development and characterization of environmentally friendly composites from poly(butylene succinate) (PBS) and almond shell flour with different compatibilizers. Composites Part B: Engineering, 144, 153-162. doi:10.1016/j.compositesb.2018.02.031

Lundahl, M. J., Klar, V., Wang, L., Ago, M., & Rojas, O. J. (2017). Spinning of cellulose nanofibrils into filaments: A review. Industrial & Engineering Chemistry Research, 56(1), 8-19. doi:10.1021/acs.iecr.6b04010

Nazrin, A., Sapuan, S. M., Zuhri, M. Y. M., Ilyas, R. A., Syafiq, R., & Sherwani, S. F. K. (2020). Nanocellulose reinforced thermoplastic starch (TPS), polylactic acid (PLA), and polybutylene succinate (PBS) for food packaging applications. Frontiers in Chemistry, 8, 1-12. doi:10.3389/fchem.2020.00213

Qian, S., Zhang, H., Yao, W., & Sheng, K. (2018). Effects of bamboo cellulose nanowhisker content on the morphology, crystallization, mechanical, and thermal properties of PLA matrix biocomposites. Composites Part B: Engineering, 133, 203-209. doi:10.1016/j.compositesb.2017.09.040

Qiu, S., Zhou, Y., Waterhouse, G. I. N., Gong, R., Xie, J., Zhang, K., & Xu, J. (2021). Optimizing interfacial adhesion in PBAT/PLA nanocomposite for biodegradable packaging films. Food Chemistry, 334, 127487. doi:10.1016/j.foodchem.2020.127487

Rostamitabar, M., Subrahmanyam, R., Gurikov, P., Seide, G., Jockenhoevel, S., & Ghazanfari, S. (2021). Cellulose aerogel micro fibers for drug delivery applications. Materials Science and Engineering: C, 127, 112196. doi:10.1016/j.msec.2021.112196

Silva, M. F., Menis-Henrique, M. E. C., Felisberto, M. H. F., Goldbeck, R., & Clerici, M. T. P. S. (2020). Bamboo as an eco-friendly material for food and biotechnology industries. Current Opinion in Food Science, 33, 124-130. doi:10.1016/j.cofs.2020.02.008

Singh, S., Gaikwad, K. K., Park, S. I., & Lee, Y. S. (2017). Microwave-assisted step reduced extraction of seaweed (Gelidiella aceroso) cellulose nanocrystals. International Journal of Biological Macromolecules, 99, 506-510. doi:10.1016/j.ijbiomac.2017.03.004

Singla, R., Soni, S., Patial, V., Kulurkar, P. M., Kumari, A., Mahesh, S., … Yadav, S. K. (2017). In vivo diabetic wound healing potential of nanobiocomposites containing bamboo cellulose nanocrystals impregnated with silver nanoparticles. International Journal of Biological

Macromolecules, 105, 45-55. doi:10.1016/j.ijbiomac.2017.06.109

Svensson, S. E., Ferreira, J. A., Hakkarainen, M., Adolfsson, K. H., & Zamani, A. (2021). Fungal textiles: Wet spinning of fungal microfibers to produce monofilament yarns. Sustainable Materials and Technologies, 28, e00256. doi:10.1016/j.susmat.2021.e00256

Theivasanthi, T., Anne Christma, F. L., Toyin, A. J., Gopinath, S. C. B., & Ravichandran, R. (2018). Synthesis and characterization of cotton fiber-based nanocellulose. International Journal of Biological Macromolecules, 109, 832-836. doi:10.1016/j.ijbiomac.2017.11.054

Vanitha, R., & Kavitha, C. (2021). Development of natural cellulose fiber and its food packaging application. Materials Today: Proceedings, 36, 903-906. doi:10.1016/j.matpr.2020.07.029

Wang, L., Ago, M., Borghei, M., Ishaq, A., Papageorgiou, A. C., Lundahl, M., & Rojas, O. J. (2019). Conductive carbon microfibers derived from wet-spun lignin/nanocellulose hydrogels. ACS Sustainable Chemistry & Engineering, 7(6), 6013-6022. doi:10.1021/acssuschemeng.8b06081

Wu, F., Misra, M., & Mohanty, A. K. (2020). Sustainable green composites from biodegradable plastics blend and natural fibre with balanced performance: Synergy of nano-structured blend and reactive extrusion. Composites Science and Technology, 200, 108369. doi:10.1016/j.compscitech.2020.108369

Xie, J., Hse, C.-Y., De Hoop, C. F., Hu, T., Qi, J., & Shupe, T. F. (2016). Isolation and characterization of cellulose nanofibers from bamboo using microwave liquefaction combined with chemical treatment and ultrasonication. Carbohydrate Polymers, 151, 725-734. doi:10.1016/j.carbpol.2016.06.011