Synthesis and Characterization of TiN Thin Films by DC Reactive Magnetron Sputtering

DOI:

https://doi.org/10.53848/ssstj.v10i2.353Keywords:

TiN thin film, N2 flow rates, Reactive magnetron sputteringAbstract

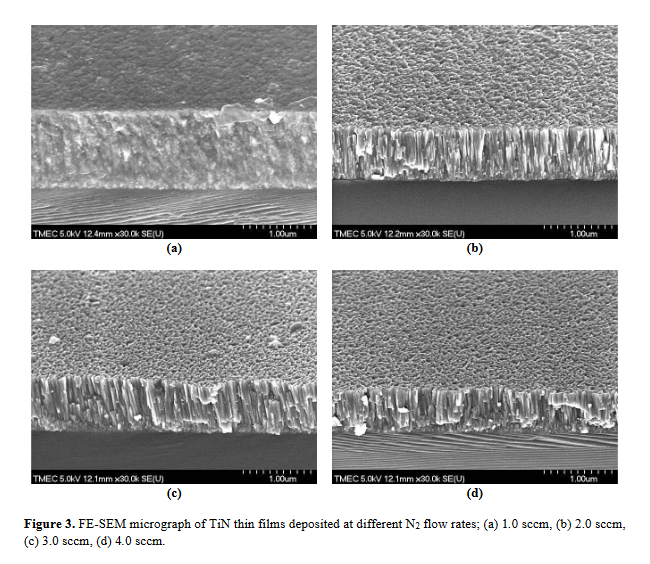

In this work, the titanium nitride (TiN) thin films were prepared on Si-wafers by using the DC reactive magnetron sputtering from a pure titanium target. The influence of N2 flow rates, in the range of 1.0-4.0 sccm, on the as-deposited TiN film’s structure was characterized by several techniques. (i) The crystal structures were studied by GI-XRD. (ii) The film’s thicknesses, microstructures, and surface morphologies were analyzed by FE-SEM. (iii) The elemental composition of films was measured by EDS. (iv) The hardness was measured by the nano-indentation. (v) The color was identified by a UV-VIS spectrophotometer. The results showed that the as-

deposited films were polycrystalline of B1-NaCl structure. The lattice constants were ranging from 4.211-4.239 Å. The as-deposited films showed a nano crystal size in the range of 17.8-24.6 nm. The thickness decreases from 1254 nm to 790 nm with following in the N2 flow rates. The concentration of Ti and N depended on the N2 flow rates. The cross-sectional analysis showed that the films had a compact-columnar structure. The hardness increased from 4 to 19 GPa with increasing in the N2 flow rates. The close to the color of 24K gold thin films in the CIE L*a*b* system was obtained by deposition in optimal N2 flow rates.

References

Ajenifuja, E., Popoola, A. P. I., & Popoola, O. M.(2019). Thickness dependent chemical and microstructural properties of DC reactive magnetron sputtered titanium nitride thin films on low carbon steel cross-section. Journal of Materials Research and Technology, 8(1), 377-384. doi:10.1016/j.jmrt.2018.02.010

Bendavid, A., Martin, P. J., Netterfield, R. P., & Kinder, T. J. (1996). Characterization of the optical properties and composition of TiNx thin films by spectroscopic ellipsometry and X-ray photoelectron spectroscopy. Surface and Interface Analysis, 24(9), 627-633. doi:10.1002/(SICI)1096-9918(19960916)24:9<627::AID-SIA149>3.0.CO;2-R

Gao, F., & Sun, W. (2019). Nonlinear finite element modeling and vibration analysis of the blisk deposited strain-dependent hard coating.Mechanical Systems and Signal Processing,121, 124-143.doi:10.1016/j.ymssp.2018.11.028

Grosso, S., Latu-Romain, L., Berthome, G., Renou,G., Le Coz, T., & Mantel, M. (2017). Titanium and titanium nitride thin films grown by dc reactive magnetron sputtering Physical Vapor Deposition in a continuous mode on stainless steel wires: Chemical, morphological and structural investigations. Surface and Coatings Technology, 324, 318-327.doi:10.1016/j.surfcoat.2017.05.089

Jithin, M., Ganapathi, K. L., Vikram, G. N. V. R.,Udayashankar, N. K., & Mohan, S. (2018).Pulsed DC magnetron sputtered titanium nitride thin films for localized heating applications in MEMS devices. Sensors and Actuators A: Physical, 272, 199-205. doi:10.1016/j.sna.2017.12.066

Kim, S. H., Park, H., Lee, K. H., Jee, S. H., Kim, D.J., Yoon, Y. S., & Chae, H. B. (2009). Structure and mechanical properties of titanium nitride thin films grown by reactive pulsed laser deposition. Journal of Ceramic Processing Research, 10(1), 49-53.

Kumar, D. D., Kumar, N., Kalaiselvam, S.,Thangappan, R., & Jayavel, R. (2018). Film thickness effect and substrate dependent tribo- mechanical characteristics of titanium nitride films. Surfaces and Interfaces, 12, 78-85.doi:10.1016/j.surfin.2018.05.002

Kusano, E. (2019). Structure-zone modeling of sputter-deposited thin films: A brief review.Applied Science and Convergence Technology,28(6), 179-185.

Lepicka, M., Gradzka-Dahlke, M., Pieniak, D.,Pasierbiewicz, K., Krynska, K., & Niewczas,A. (2019). Tribological performance of

titanium nitride coatings: A comparative studyon TiN-coated stainless steel and titanium alloy. Wear, 422-423, 68-80.

Mitterer, C. (2014). PVD and CVD hard coatings. In V. K. Sarin (Ed.), Comprehensive hard materials (pp. 449-467). Oxford, UK: Elsevier. doi:10.1016/B978-0-08-096527-7.00035-0

Pelleg, J., Zevin, L. Z., Lungo, S., & Croitoru, N.(1991). Reactive-sputter-deposited TiN films on glass substrates. Thin Solid Films, 197(1-2), 117-128. doi:10.1016/0040-6090(91)90225-M

Ponon, N. K., Appleby, D. J. R., Arac, E., King, P.J., Ganti, S., Kwa, K. S. K., & O'Neill, A.(2015). Effect of deposition conditions and post deposition anneal on reactively sputtered titanium nitride thin films. Thin Solid Films, 578, 31-37. doi:10.1016/j.tsf.2015.02.009

Santecchia, E., Hamouda, A. M. S., Musharavati, F.,Zalnezhad, E., Cabibbo, M., & Spigarelli, S.(2015). Wear resistance investigation of titanium nitride-based coatings. Ceramics International, 41(9), 10349-10379.doi:10.1016/j.ceramint.2015.04.152

Thampi, V. V. A., Bendavid, A., & Subramanian, B.(2016). Nanostructured TiCrN thin films by Pulsed Magnetron Sputtering for cutting tool applications. Ceramics International, 42(8),9940-9948.doi:10.1016/j.ceramint.2016.03.095

Zhang, D. H., Yang, T. L., Ma, J., Wang, Q. P., Gao,R. W., & Ma, H. L. (2000). Preparation of transparent conducting ZnO:Al films on polymer substrates by r. f. magnetron sputtering. Applied Surface Science, 158(1-2),43-48. doi:10.1016/S0169-4332 99 00591-7

Zhang, H., Li, Z., Ma, C., He, W., Cao, X., & Li, Y.(2019). The anti-sand erosion performance of TiN films fabricated by filtered cathodic vacuum arc technique at different nitrogen flow rates. Ceramics International, 45(8),10819-10825.doi:10.1016/j.ceramint.2019.02.157

Zhang, S., Yan, F., Yang, Y., Yan, M., Zhang, Y.,Guo, J., & Li, H. (2019). Effects of sputtering gas on microstructure and tribological properties of titanium nitride films. Applied Surface Science, 488, 61-69.doi:10.1016/j.apsusc.2019.05.148

Zhou, T., Liu, D., Zhang, Y., Ouyang, T., & Suo, J.(2016). Microstructure and hydrogen impermeability of titanium nitride thin films deposited by direct current reactive magnetron sputtering. Journal of Alloys and Compounds,688, 44-50. doi:10.1016/j.jallcom.2016.06.278

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Suan Sunandha Rajabhat University

This work is licensed under a Creative Commons Attribution 4.0 International License.