Mechanical Properties Enhancement of the Cement Mortar by Synthetic Zeolite Polymer Composites

DOI:

https://doi.org/10.53848/ssstj.v10i1.429Keywords:

Cement mortar, Zeolite, Pozzolan, EttringiteAbstract

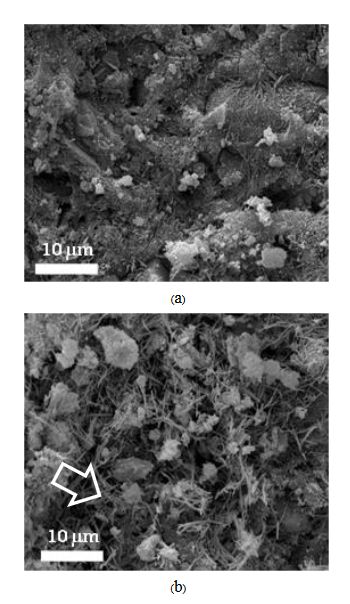

The performance of cement mortar can be improved with additives based on waste by-products. Synthetic zeolite polymer composites (referred as SZPC) produced from the combination of solid waste ashes with a selective acrylic compound was used as a cement mortar additive. The effect of SZPC as an additive on hydration reaction of ordinary Portland cement (referred as OPC) at different amounts of SZPC, from 1-4% of OPC weight, as well as microstructure and mechanical behavior of the cement mortar are determined. The results from the hydration reaction rate test showed that the optimum amount of SZPC as the additive was 2% of OPC weight. Compressive strength and flexural strength of the cement mortar after 1, 7, 14 and 28 days of curing increased, with the largest

increases at the early stage. Additions of SZPC, synthesized by a waste by-product, improved mechanical behavior of cement mortars supporting sustainable development and the circular economy.

References

Chakartnarodom, P., Wanpen, S., Prakaypan, W.,Laitila, E. A., & Kongkajun, N. (2022).Development of high-performance fiber cement:

A case study in the integration of circular economy in product design. Sustainability, 14(19). doi:10.3390/su141912263

Devi, K. S., Lakshmi, V. V., & Alakanandana, A. (2018). Impacts of cement industry on environment - An overview. Asia Pacific Journal

of Research, 1, 156-161.

Gbekou, F. K., Benzarti, K., Boudenne, A., Eddhahak, A., & Duc, M. (2022). Mechanical and thermophysical properties of cement mortars

including bio-based microencapsulated phase change materials. Construction and Building Materials, 352. doi:10.1016/j.conbuildmat.2022.129056

Girskas, G., Skripkiūnas, G., Šahmenko, G., & Korjakins, A. (2016). Durability of concrete containing synthetic zeolite from aluminum

fluoride production waste as a supplementary cementitious material. Construction and Building Materials, 117, 99-106.

doi:10.1016/j.conbuildmat.2016.04.155

Harrisson, A. M. (2019). Constitution and specification of Portland cement. In P. C. Hewlett & M. Liska (Eds.), Lea's chemistry of cement and concrete (5th ed.) (pp. 87-155). Oxford: Butterworth-Heinemann.doi:10.1016/B978-0-08-100773-0.00004-6

He, W., Liang, J., Xu, J., Cui, N., Jiao, Z., & Zhou, J. (2022). Nanoarchitectonics effect of few-layer graphene on the properties of cement mortar.Construction and Building Materials, 349.doi:10.1016/j.conbuildmat.2022.128738

Jiang, Y., Li, B., Liu, S., He, J., & Hernandez, A. G. (2022). Role of recycled concrete powder as sand replacement in the properties of cement mortar.Journal of Cleaner Production, 371.doi:10.1016/j.jclepro.2022.133424

Maljaee, H., Paiva, H., Madadi, R., Tarelho, L. A. C., Morais, M., & Ferreira, V. M. (2021). Effect of cement partial substitution by waste-based biochar in mortars properties. Construction and Building Materials, 301. doi:10.1016/j.conbuildmat.2021.124074

Marchon, D., & Flatt, R. J. (2016). Mechanisms of cement hydration. In P.-C. Aïtcin & R. J. Flatt (Eds.), Science and technology of concrete

admixtures (pp. 129-145). UK: Woodhead Publishing.

McCarthy, M. J., & Dyer, T. D. (2019). Pozzolanas and pozzolanic materials. In P. C. Hewlett & M. Liska (Eds.), Lea's chemistry of cement and concrete(5th ed.) (pp. 363-467). Oxford: Butterworth-Heinemann.

Pahuswanno, P., Chakartnarodom, P., Ineure, P., & Prakaypan, W. (2019). The influences of chemical treatment on recycled rejected fiber cement used as fillers in the fiber cement products. Journal of Metals, Materials and Minerals, 29(3), 66-70.

doi:10.14456/jmmm.2019.36

Praveen Kumar, K., & Radhakrishna, K. (2015). Strength and workability of cement mortar with manufactured sand. International Journal of Research in Engineering and Technology, 4, 186-189. doi:10.15623/ijret.2015.0413030

Shi, T., Liu, Y., Zhao, X., Wang, J., Zhao, Z., Corr, D. J., & Shah, S. P. (2022). Study on mechanical properties of the interfacial transition zone in carbon nanofiber-reinforced cement mortar based on the PeakForce tapping mode of atomic force microscope. Journal of Building Engineering, 61. doi:10.1016/j.jobe.2022.105248

Sonprasarn, P., Chakartnarodom, P., Ineure, P., & Prakaypan, W. (2019). Effects of the chemical treatment on coal-fired bottom ash for the utilization in fiber-reinforced cement. Journal of Metals, Materials and Minerals, 29(4), 55-60.doi:10.14456/jmmm.2019.47

Tanasalagul, R., Pantongsuk, T., Srichumpong, T., Junsomboon, J., Prakaypan, W., & Chaysuwan, D. (2019). Effect of zeolite on early strength of Portland cement mortars. Key Engineering Materials, 798, 358-363. doi:10.4028/www.scientific.net/KEM.798.358

Tran, Y. T., Lee, J., Kumar, P., Kim, K.-H., & Lee, S. S. (2019). Natural zeolite and its application in concrete composite production. Composites Part B: Engineering, 165, 354-364. doi:10.1016/j.compositesb.2018.12.084

Velenturf, A. P. M., & Purnell, P. (2021). Principles for a sustainable circular economy. Sustainable

Production and Consumption, 27, 1437-1457. doi:10.1016/j.spc.2021.02.018

Yu, J., Qian, J., Tang, J., Ji, Z., & Fan, Y. (2019). Effect of ettringite seed crystals on the properties of calcium sulphoaluminate cement. Construction and Building Materials, 207, 249-257. doi:10.1016/j.conbuildmat.2019.02.130

Zhang, J., Wang, Z., Yao, Y., Tang, R., Li, S., Liu, X., & Sun, D. (2021). The effect and mechanism of C–S–H-PCE nanocomposites on the early

strength of mortar under different water-to-cement ratio. Journal of Building Engineering, 44. doi:10.1016/j.jobe.2021.103360

Zhang, M. H., & Malhotra, V. M. (1995). Characteristics of a thermally activated alumino-silicate pozzolanic material and its use in

concrete. Cement and Concrete Research, 25(8),1713-1725. doi:10.1016/0008-8846(95)00167-0

Zhao, X. (2010). Porous materials for direct and indirect evaporative cooling in buildings. In M.R. Hall (Ed.), Materials for energy efficiency and thermal comfort in buildings (pp. 399-426). Oxford: Woodhead Publishing.

Zhou, W., Duan, L., Tang, S. W., Chen, E., & Hanif, A. (2019). Modeling the evolved microstructure of cement pastes governed by diffusion through barrier shells of C–S–H. Journal of Materials Science, 54, 4680-4700. doi:10.1007/s10853-018-03193-x